Hélène Pilkiewicz — October 15, 2018

Plastic part or sand castle?

In a previous article, we explained how the shape of a part plays a crucial role in its ability to be removed from its mold.

Once we have decided the shape of the part and how the mold will open, we can finally design the technical bits, such as the grid that makes the part stronger, or the screw holes that we use for assembly.

If we want to be able to remove the part from the mold, we have to make sure that any bit we add has a correct shape (i.e. can be removed from the mold as well). We also need to make sure that no surface is vertical.

Screw holes shape

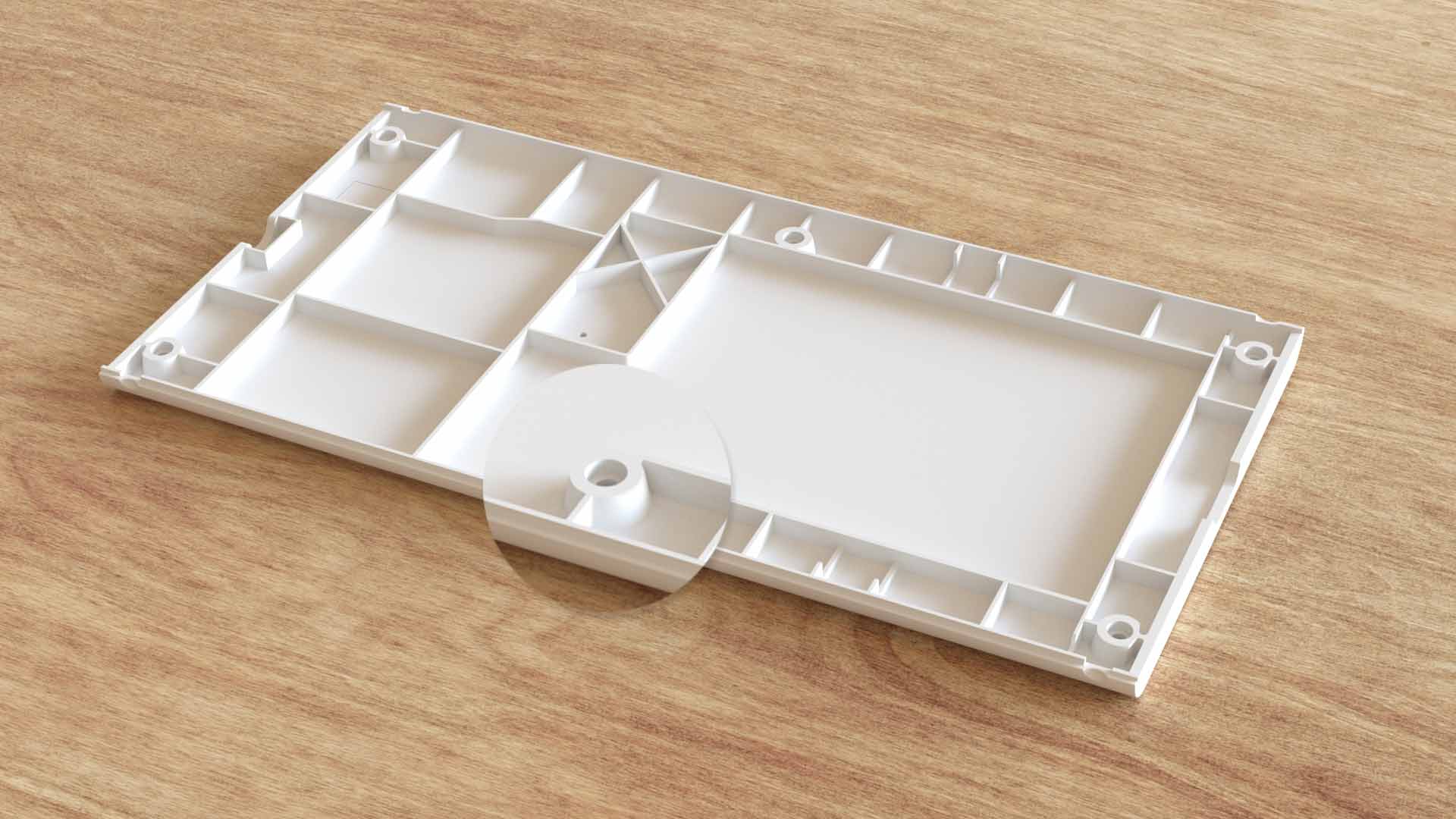

Let’s look at one of the screw hole shapes on the back cover, as highlighted below.

As you can see, its outside is not perfectly upright. It has a slope of a few degrees.

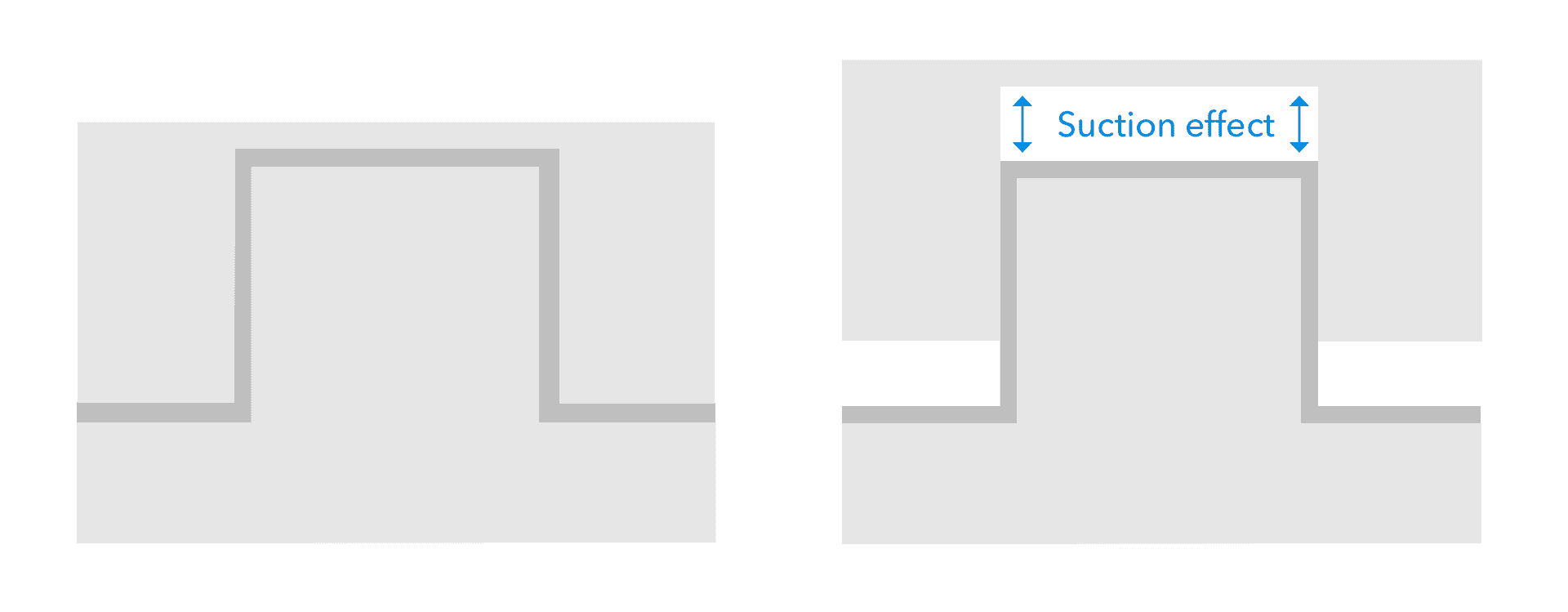

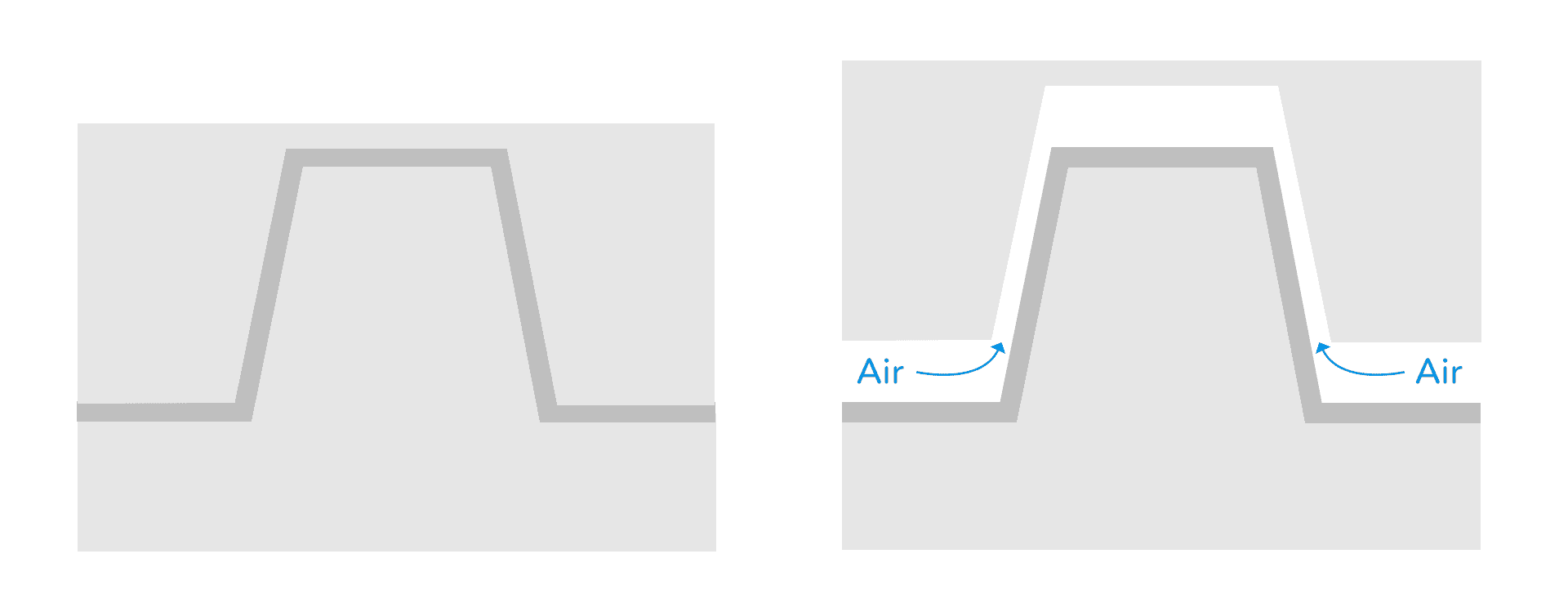

We use this feature to allow air to get into the mold easily when we remove the part. If the air can not get in - as it would if the surface were upright - a suction effect happens. This makes it almost impossible to remove the part from its mold.

The mold has vertical surfaces, the air cannot get in, there is a suction effect.

As the surface has a slight slope, the air can get in. We can easily remove the part.

If you remember the bucket you used at the beach to make sand castles, then you probably remember that they had a slight slope as well. That way you could actually unmold your sandy masterpiece without breaking it. But also, because most of these buckets are made using plastic injection themselves, they also had to be removed from their own mold at some point!

The clearance angle

The angle of that slope is called the clearance angle.

And it is not just for cylindrical shapes. Everything is designed with clearance angles: none of the surfaces you can see on an injected product can be perfectly upright. This applies for example to the lines you can see inside the back cover to make it more rigid, or even to the outside surfaces.

The actual value of the clearance angle depends on a few parameters, such as the depth of the mold cavity or the chosen aspect of the plastic material. For instance, the angle will be bigger for a rough surface than a smooth one.

So, once you have correctly designed the shape of your part, found a parting line that works, and added a clearance angle to all the surfaces, you should be able to remove your brande new part from its mold quite easily!

Hélène Pilkiewicz — Industrial Engineer

Hélène is the creator of all the physical aspects of the NumWorks graphing calculator. She joined our team in September 2016 as an Industrial Engineer. Hélène has a Master's in Industrial Engineering. She works on everything involved with producing the calculator: design of plastic parts, choice of suppliers and monitoring of production and quality. Every time you use your calculator, you are touching Hélène's masterpiece! When not tinkering in her workshop, Hélène is finding new and interesting ways to eat her favorite food: broccoli!